our blog

What to Look for While Choosing an Industrial Shed: From an Industrial Realtor’s Perspective

- rightspaces

- Est.Time - 5 mins

- Lastmile Delivery Centers: Typically darkstores within city limits.

- Small Businesses or Workshops: Typically need approximately 5,000–10,000 sq. ft. for operations like light manufacturing or assembly.

- Mid Mile Sorting Centers: May require approximately 25,000 sq. ft. or more, depending on inventory volume.

- Heavy Manufacturing or Industrial Use: Could demand over approximately 50,000 sq. ft. to accommodate large machinery, raw materials, and finished goods.

- Fulfilment Centers: Large scale warehousing facilities with automation.

Choosing an industrial shed is more than just finding a space. It’s about aligning the property’s specifications with the business’s operational needs and growth plans. Here are 10 points from an industrial realtor’s perspective to consider for selecting the right industrial shed in the Indian context.

1. Location and Accessibility

Proximity to key transportation hubs—such as highways, ports, and airports—is crucial. Easy access to these facilities can significantly reduce logistics costs and enhance supply chain efficiency.

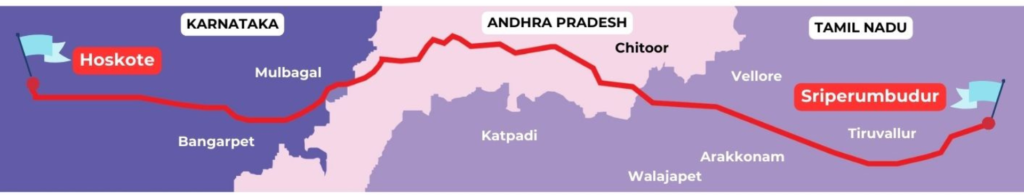

Additionally, consider future development projects in the area that can enhance connectivity and reduce transit times. For example in Chennai, projects like the Bengaluru-Chennai Expressway are expected to significantly reduce travel time between the two cities, improving logistics efficiency and access to major markets. Investing in a location with such upcoming developments can ensure better operational capabilities and increase the property’s long-term value.

2. Standalone Industrial Sheds vs. Industrial Parks

Another important decision is choosing between a standalone industrial shed and a shed located within an industrial park. Both options have their own advantages:

Standalone Industrial Sheds:

- Offer greater customization for business-specific requirements.

- Provide more privacy, making them ideal for businesses with sensitive operations.

- Suitable for enterprises that require more open area for independent infrastructure and operations.

Industrial Parks:

- Promote a collaborative ecosystem where businesses can benefit from proximity to suppliers, distributors, or related industries.

- Offer shared infrastructure such as power, water, waste management, and security, reducing operational overheads.

- Often strategically located with better connectivity and access to skilled labor pools.

- Provides room for scalability.

The choice depends on your operational model, budget, and the nature of your industry.

3. Proximity to Neighborhood Ecosystems

When selecting an industrial shed, it’s important to consider the presence of a supportive ecosystem with similar or complementary industries. These clusters provide a network of suppliers, raw material vendors, repair shops, and ancillary service providers that can enhance operational efficiency and eventually contribute to cost savings.

For example:

- A food processing unit can benefit from proximity to packaging material suppliers or cold storage facilities.

- An automotive parts manufacturer can thrive in a mini-market with other automobile-focused industries, ensuring faster access to tools, parts, and technical expertise.

Being part of such a community can lower logistics costs, encourage collaborations, and streamline supply chain management.

4. Infrastructure and Amenities

A well-constructed shed with robust infrastructure is vital. Features like high ceilings, wide column spacing, and durable flooring can accommodate heavy machinery and streamline operations. Additionally, ensure the availability of essential utilities such as water, electricity, and waste management systems.

5. Scalability and Flexibility

Businesses often experience growth or changes in operational requirements. Opt for sheds that offer flexibility in design and layout, allowing for future expansions or modifications without significant overhauls. This adaptability can be a cost-effective solution in the long run.

6. Safety and Compliance

Adherence to safety standards and regulations is non-negotiable. Ensure the shed complies with local building codes, fire safety norms, and environmental regulations. Incorporating safety features like fire suppression systems, emergency exits, and proper ventilation is essential for a secure working environment.

7. Cost Considerations

While it’s tempting to opt for the most affordable option, it’s crucial to balance cost with quality and functionality. Consider the total cost of ownership, including maintenance, utilities, and potential renovations. A well-built, durable shed may have a higher initial cost but can lead to savings over time due to reduced maintenance and operational efficiencies.

8. Labor Availability

The availability of a skilled workforce and labour pool clusters in the vicinity can influence operational efficiency with labour availability being an important deciding factor, this cannot be overlooked.

9. Environmental Impact

Sustainability is becoming increasingly important. Opt for sheds constructed with eco-friendly materials and those that incorporate energy-efficient designs. Features like natural lighting, rainwater harvesting, and solar panels can reduce operational costs and appeal to environmentally conscious stakeholders. To start with, look for sheds that can accomodate solar panels in the roof. Some certifications such as LEED rating in warehousing mean this would be long term savings in operational cost.

10. Technological Integration

In today’s digital age, integrating technology into industrial operations is paramount. Ensure the shed is equipped to handle technological advancements, such as automation systems, IoT devices, and advanced security systems. This preparedness can future-proof your operations and provide a competitive edge.

Conclusion

Selecting the right industrial shed requires a holistic approach, considering factors that align with both immediate operational needs and long-term strategic goals. By meticulously evaluating these aspects, businesses can secure a facility that not only meets current requirements but also supports future growth and success. Whether opting for a standalone shed, joining an industrial park, or leveraging a neighborhood mini-market, the right choice will position your business for operational efficiency and sustainable growth.

Recommended Articles

About the contributor

Anjanakshi is an architect and a valued team member at Rightspaces. With a passion for design and branding, she stays curious, loves reading, writing, and keeping up with market insights in the industrial real estate space.